There are many sectors of industry that use thermal processing in their production cycle. Many of these rely on furnaces that are electrically heated and hence need materials that have high thermal stability and high electrical loading capability. They also need to be resistant to aggressive media, thermal shock and be chemically pure so as not to deposit any unwanted elements during thermal processing. The use of Graphite parts offer the user the possibility to work at temperatures that are beyond the capability of metal and ceramic elements. These are usually not used above 2000ºC whereas graphite is capable of withstanding temperatures up to 3000ºC.

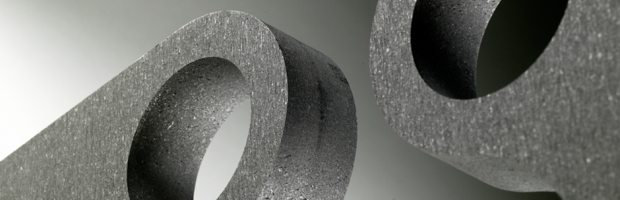

The properties of graphite and c/c composite make them the ideal materials of choise for components used in furnace applications including vacuum and inert atmosphere. graphite is easily machined so complex shapes can be made to suit the requirements of the furnace. Schunk’s c/c composite has been developed as a high strength to weigth ratio material suitable for many applications including carrier trays, structural parts and heater elements. The material has excellent shock and chemical resistance whilst having a low CTE and high purity. Due to low thermal conductivity and high emissivity Schunk’s graphite felt is especially appropriate for the use as insulation material. It provised excellent resistance to chemical attack and prolonged lifespan due to its high purity. Graphite soft felt is characterized by high flexibility and ease of processing. Rigid felt is an insulation material with a high dimensional stability.