Industries involved with processing molten liquids, in particular metals such as Iron, Aluminium, Copper and Precious metals and glass, use casting and metal treatment techniques that require the use of Graphite materials resistant to attack by the molten liquid. These Graphite materials must also not affect the final composition of the cast metal or deposit any hard particles in the melt that could cause problems during any subsequent post machining operations.

Continuous casting operations demand the use of Graphite for a number of reasons including:

- A resistance to wetting by the molten metal

- Efficient heat removal

- Excellent thermal shock resistance

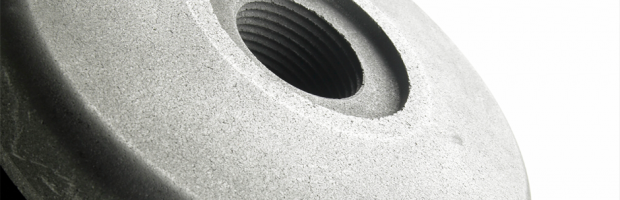

For processing aluminium alloys during such operations as degassing, Graphite shafts and rotors are ideal for the same reasons. Extended life is available with GRAPHOX treated Graphite. Tokai uses a post-machining technique that ensures the Graphite parts are completely impregnated during the process.