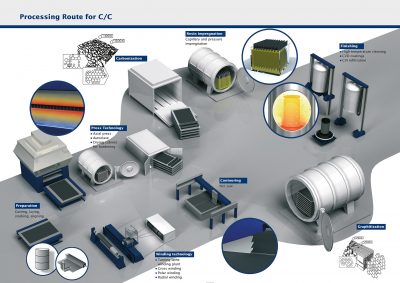

Carbon fibre reinforced carbon – C/C

Compared to conventional hightemperature materials, C/C materials are characterised by high performance across a wide spectrum of special properties. These properties enable the implementation of different solutions in the hightemperature range, where conventional materials fail.

C/C material for structural applications

The mechanical properties of C/C materials are determined, alongside the fibres used, by the matrix and fibre architecture and end annealing temperature. In contrast to conventional ceramic and metallic materials, the strength and rigidity of carbon material increases around 15 % with rising temperatures. At high temperatures, C/C components are largely in a tension-free state. The different material qualities are tailored composite structures for use under extreme conditions.

Failure behaviour

In contrast to conventional ceramic materials, the C/C composite structure has the advantage of quasiductile or pseudoplastic behaviour,vs. a sudden total failure during stress on the body. This fracture behaviour is not the same as the plastic deformation that can be seen with metallic materials. However, it still tolerates a greater degree of stress without causing complete failure of the component, compared to conventional ceramics. Under the applied load, a few strands of fibre first crack, causing a fibre pull-out effect, a leading indicator of failure. Component failure occurs only after repeated cyclic loading, where the composite body has high residual strength. The composite structure of a C/C component shows no brittle fracture with overuse, making it possible to use nails in this type of material. This is made possible both by the pseudo plasticity and the open porosity.

Thermal shock resistance

The superior thermal shock resistance, compared to conventional ceramic and metallic materials, makes C/C a unique high-temperature material. Due to the microstructure, thermal stresses are reduced. C/C composite bodies, therefore, have high thermal shock resistance.

C/C properties

- high damage tolerance, pseudoplastic fracture behaviour

- low density (1.3 – 1.8 g/cm3)

- low thermal expansion coefficient in fiber direction

- no brittleness at high temperatures over the entire lifespan

- high resistance to thermal shock

- no stress under thermo-cyclic load

- very good creep resistance at high temperatures

- good chemical stability

- adjustable electrical and thermal properties, dependent on fiber reinforcement and heat treatment

- over 350°C reaction with oxygen

- usable at temperatures of up to 2,800°C under vacuum or inert gas

- electroconductive

- anisotropy; flexural and tensile strength, electrical conductivity and thermal conductivity have different values in materials with C fibres orientated in the direction of the fibre than if they are perpendicular to the fibre or layer direction

- low thermal conductivity