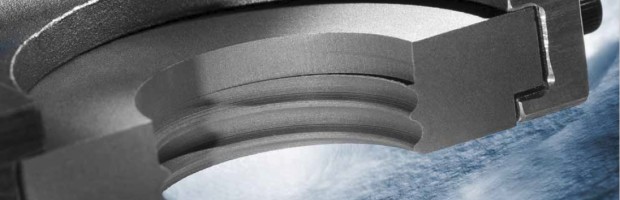

Every stage of the production process where hot glass is poured, guided and directed results in contact with components made of other materials. The functional safety and material properties of these materials are crucial for an efficient, trouble-free production process and for the excellent finish of the glass products. That‘s why we manufacture these components from carbon. Carbon is like no other material, and its unique properties make it ideal for use in the glass industry.

- Carbon prevents stress cracks in the glass because its thermal conductivity is substantially lower than other metals.

- Carbon leaves no buildup on glass products whatsoever because it has extraordinary chemical resistance.

- Carbon allows for high durability of handling components because it is extremely resistant to high temperatures and oxidation.

For components with extreme mechanical stress ability, Schunk offers additional carbon-fibre-reinforced materials. We accompany our customers through the entire planning and development process. We support you in both the design and dimensioning of your component and in the choice of the most efficient form of production.